Protecting Ham Equipment

Protecting Ham Equipment

As Hams we tend to gather lots of electronic toys and often pack them around with us to various operating locations. These instruments can be fragile and prone to damage from falling or banging around. This project shows the building of a sturdy case for my Nano VNA using a 3D printer.

The first step of building a case is to check the vast public libraries of free 3D models to see if any are available that will achieve my needs as is or with minimal changes. I wanted a case for my Nano VNA as the supplied cardboard box was not good for long term protection. I found a case designed specifically for my unit on Printables.com it was designed for my unit and would be a perfect fit. I downloaded the model file to my computer.

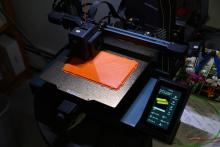

Once on my system I split the model into the constituent parts – Case top/Bottom, Filler Top/Bottom, latches and the seal. I then proceeded to slice the model part into g-code which is the low-level language used to control the printer. The case was now ready to print.

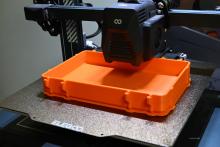

For the actual case and latches I wanted a sturdy plastic that would hold up to use and be UV safe. Three plastics seemed suitable to me PETG, ASA, and ABS. I haven’t worked with ABS so far as it is tricky and produces fumes while printing. PETG can be a bit brittle. ASA is similar to ABS in strength and also provides UV resistance. It is a bit easier to work with and produced less fumes. So, I decided ASA would be used for the case. It is much slower to print so the models would take many hours to complete.

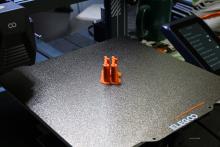

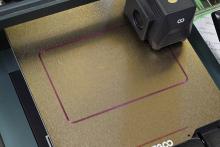

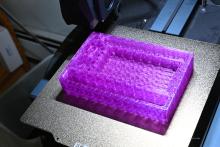

For the seal and interior, a soft plastic is needed, TPU 94A is the selection of choice. It is amazingly strong for a flexible plastic and when printed in low infill levels it is quite spongy. For this project I used 7% infill with a single layer for the top and sides and double for the base. The model requires M3 by 30mm bolts to form the hinge and latch attachments. Some would use a piece of the filament for this task, but metal bolts are stronger and not prone to breakage.

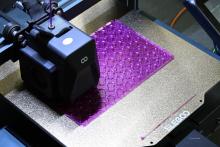

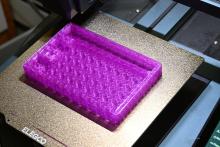

In producing the case I used a raft for the two case pieces to ensure better cohesion to the build plate. This does create a bit more clean up work on the case but it reduces warping. The TPU did not require any adhesion support. I printed the two case halves first and then the latches. This completed my work with ASA. Then came the tiny seal followed by the two inner fillers. The final result was a well-built sturdy case that will be watertight and able to withstand some serious abuse.

The major draw back of this lovely case was that my wife saw it and asked me to make her one for her sewing tools! For her project I reworked the case dimensions and will create a different interior.

The printables link for the case is: https://www.printables.com/model/991671-nanovna-h4-rugged-box